Swann-Morton Limited

Founded in Sheffield during 1932, Swann-Morton have become a world leader in the manufacture of surgical blades, scalpels and handles. It is a name respected globally for quality, precision, consistency and reliability and recognised for combining traditional blade making skills with the latest technology. The preferred choice of many of the World`s surgeons, the wide and varied range of products consisting of around 70 individual blades shapes and 30 different handles is also used extensively by other healthcare professionals such as G.P.s, Nurses and Paramedics along with practitioners in the associated fields of Dentistry, Podiatry and Veterinary surgery.

Company details

Find locations served, office locations

- Business Type:

- Manufacturer

- Industry Type:

- Medical Equipment

- Market Focus:

- Globally (various continents)

- Year Founded:

- 1932

This company also provides solutions for other industrial applications.

Please, visit the following links for more info:

Exporting to over 100 countries around the World, ...

Exporting to over 100 countries around the World, Swann-Morton have established an extensive network of overseas distributors supporting the local customer base and ensuring service levels of the highest standard are maintained at all times.

Swann-Morton has two overseas subsidiaries Swann-Morton/Sinner based in Peynier, France and J.K.Surgical based in Poznan Poland.

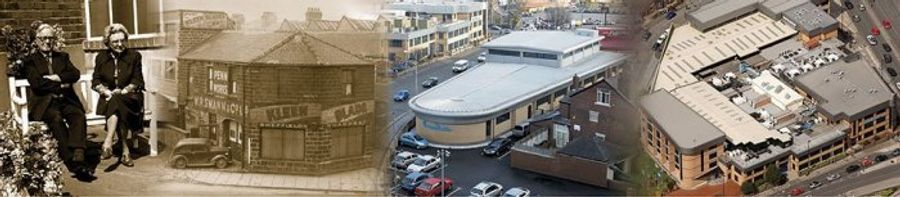

History

In this section, you can find more information relating to our company history, our policy and accreditations.

1932 to PresentMr WR Swann, Mr JA Morton and Miss D Fairweather founded the business in August 1932 to manufacturer and sell razor blades. True to their philosophy, even before they began trading, the founders drew up four statements to guide them in their entry into the capitalist world. Mr Swann's founding principles

- Claims of individuals producing in an industry came first, before anything else, and must always remain first. They are the human beings on which everything is built.

- If the industry cannot pay the rightful reward of labour (while they are producing for profit for the owners) then a new policy is required on the part of the management to make it do so.

- If the management can't do the job, then a new management is required, as well as a new policy.

- Individuals in any industry have a perfect right to demand and see that this objective is reached, because they produce the goods.

These four statements, written in Walter R Swann's handwriting, are displayed at Swann-Morton's head office and remain the principles that guide the business today.

After many years of research and development the emphasis was changed from razor blades to surgical blades. With the market for surgical blades growing considerably. By 1957 Swann-Morton was manufacturing over 38 million blades each year. During the mid 40's Mr JA Morton decided to leave the company to pursue other interests leaving Walter Swann and Doris Fairweather as remaining co-directors. Mindful of the future security of the company, the workforce and its founding principles a trust was formed to administer the company within which the employees had a 50% share and the remaining 50% placed in a charitable trust. It is this unique culture that inspires quality and commitment, and Swann-Morton's staff are very proud to be a part of this.

In the 1960's demand for sterilised surgical blades increased and Swann-Morton developed, with the expertise of UKAE at Wantage, a sterilisation process using Cobalt 60 gamma radiation. It was one of the first commercial plants of its kind in the world and enabled Swann-Morton to be completely self sufficient for all its sterilisation requirements. Today the irradiation and microbiological facilities are offered under contract to other healthcare manufacturers from Swann-Morton (Services) Limited and Swann-Morton (Microbiological Laboratory Services) Limited.

At the turn of the new century Swann-Morton marked its progress and achievements by embarking on an extensive expansion programme involving major construction works to increase the size of despatch, sterile storage, the laboratory and overall production facilities. The subsequent building of Cobb Works across from the main site in September 2006, providing purpose built space for the R&D and engineering departments and then Cygnet works in October 2008, some 400 metres away, adding much needed storage for the raw material stock, underlines a policy of ongoing investment.

The elements that combine to make Swann-Morton the success story it is today has helped to sustain it through the unprecedented economic challenges currently being presented by the downturn in the Global markets and will carry it forward with confidence and purpose. The desire for on-going improvement, the hard work ethic of all its employees and a policy of promotion from within will help sustain it as a world leader and undoubtedly take Swann-Morton to even greater heights to the benefit of the company, the employees and the customers.

Swann-Morton's directors would like to take this opportunity to thank all staff past and present, customers and suppliers for their commitment and continuing support.

Quality Assurance

Swann-Morton Limited is accredited to ISO 13485, the International Standard for Quality Management Systems for medical device companies. As well as this Swann-Morton Limited is accredited to MDSAP (Medical Device Single Audit Programme) demonstrating that the company has been audited and conforms with, as well as ISO 13485:2016, Australia – Therapeutic Goods (Medical Devices) Regulations, 2002, Schedule 3 Part 1 (excluding Part 1.6) – Full Quality Assurance Procedure, Therapeutic Goods (Medical Devices) Regulations 2002, Schedule 3 Part 4 – Production Quality Assurance Procedure; Brazil – RDC ANVISA n.16/2013, RDC ANVISA n. 23/2012, RDC ANVISA n. 67/2009; Canada Medical Device Regulations – Part 1 – SOR 98/282; Japan – MHLW Ministerial Ordinance 169, Article 4 to 68, PMD Act AND USA – 21 CFR 820, 21 CFR 803, 21 CFR 806, 21 CFR 807 – Subparts A to D

Quality Assurance indicates our firm commitment to producing quality products. The quality assurance team maintain continuous quality audits on all production lines to ensure consistency to the highest standards. Continuous checks are carried out at every stage of production by roving inspectors and at static inspection points.

The QA/RA Manager and team deal promptly with any customer complaints or quality issues that may arise. The team are there to also discuss any aspects of the product or quality system.

AccreditationsView Quality, Environmental and Energy accreditations, Health & Safety and Sterilisation information. Includes certificate downloads.

Ethical TradingWe are fully aware of the responsibility we bear towards our customers, employees and the communities in which we work, so we have applied a strict set of ethical values to guide us in our business dealings; these include but are not limited to an Ethical Trading Policy and a Supplier Code of Conduct. These can be viewed here.

Environmental and EnergyThe W.R. Swann Group will continually improve its environmental performance in line with its Environmental Policy by implementing and maintaining an Environmental Management System, which includes developing, maintaining and achieving objectives and targets.

The W.R. Swann Group is committed to responsible Energy Management and will practice energy efficiency throughout all of our facilities, plant and equipment wherever it is cost effective to do so. Energy Management plays a key role in our business.

Gender Pay GapView our gender pay gap report and narrative.

Data ProtectionYou can view our Data Protection Policy, Employee Privacy Notice and Job Applicant Privacy Notice here.